Pakistani Researchers has developed an antibacterial fabric that can instantly kills bacteria and can be used in wound dressing, masks, lab coats and several kinds of packaging materials. This fabric is also less expensive and affordable.

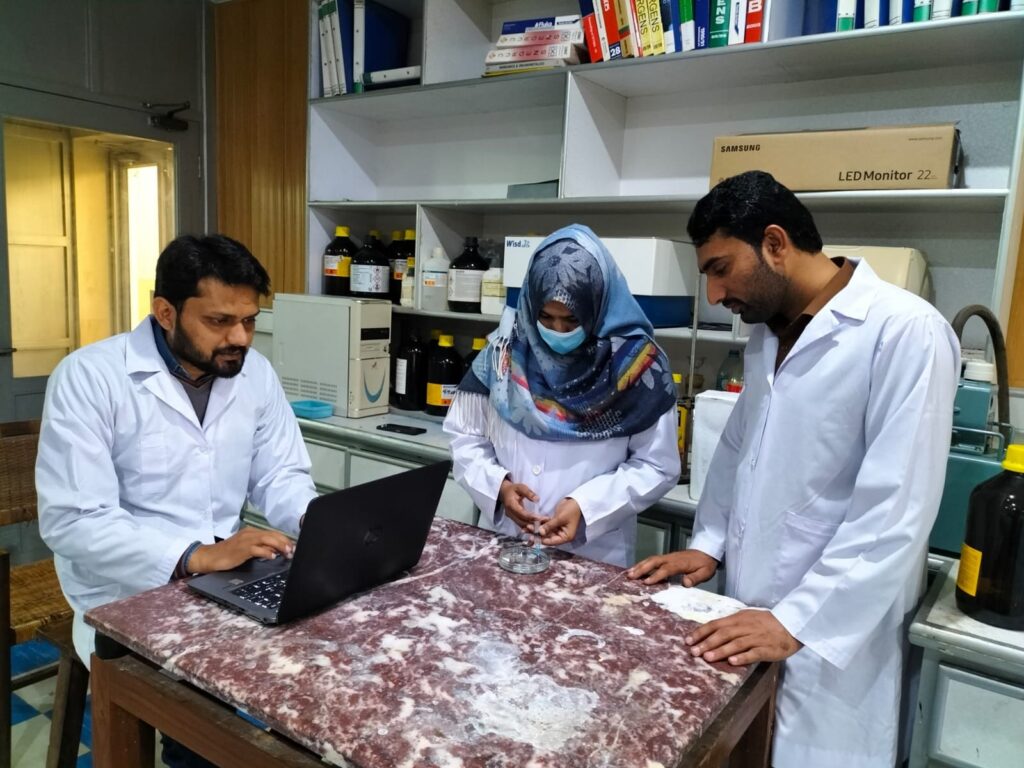

The antibacterial fabric development was the joint effort of multiple Pakistani institutes and scholars including International Centre for Chemical and Biological Sciences (ICCBS) at the University of Karachi, Government College University, Faisalabad, Nishtar Medical University Bahauddin Zakariya University, Multan and Abasyn University, Islamabad.

The research team led by Associate Professional Division of Analytical Chemistry, Bahauddin Zakariya University tested an eco-friendly component called chitosan and silver nanoparticles modified fabric for four types of bacteria.

It treated regular fabric with alkali to create active sites in it for modification. The fabric was then dipped in the chitosan and silver nanoparticles, which gave it an extra, invisible layer. The coating allows for protection against microbes but with minimal cytotoxicity and synergistically. Consequently, the fabric was found to be highly effective in preventing microbial contamination.

Dr. Majeed stated that the coating has active antimicrobial properties and instantly kills bacterial strains upon contact.

The antibacterial fabric development was the joint effort of multiple Pakistani institutes and scholars including International Centre for Chemical and Biological Sciences (ICCBS) at the University of Karachi, Government College University, Faisalabad, Nishtar Medical University Bahauddin Zakariya University, Multan and Abasyn University, Islamabad.

Pathogen Test

The team loaded the fabric with four common types of bacteria to test the antimicrobial properties of the fabric. These included Staphylococcus aureus, Enterobacter aerogenes, Micrococcus luteus, and E.coli, which cause infections, hospital contamination, diarrhea, and pneumonia among other infectious and sometimes incurable diseases.

When the antibacterial patch was compared to normal fabric in laboratory experiments, it showed 85 percent efficacy to kill the bacteria and even prevented it from spreading to the other parts as a colony.

The fabric is reliable as its quality and strength remained uncompromised during the whole process. It does not lose its characteristics and contents even after being rinsed 10-15 times with water.

The results proved that the fabric treatment method can be used for hospital fabrics, masks, and food packaging materials.

Meanwhile, more specialized tests are underway.

Shelf Life

Shelf life and storage are essential to the commercialization of antimicrobial fabric, for which several samples were rigorously checked in light and the dark.

One piece was continuously exposed to UVA light for six weeks to determine the efficacy of the antimicrobial procedure. Another cloth was put in the dark in the same observational settings, and the fabric retains its maximum antimicrobial properties even after 12 weeks.

Subsequently, senior Ph.D. scholar and research co-author, Dr. Tayyab Raza stated, “The overall treatment and modification of fabric do not affect the essential qualities of fabric”.

Dr. Majeed commented that the pandemic had halted many imports, including medical supplies, which led the team to study medical fabrics as an emerging field with research on anti-bacterial material. It decided to develop the material locally, while the method is going to be patented.